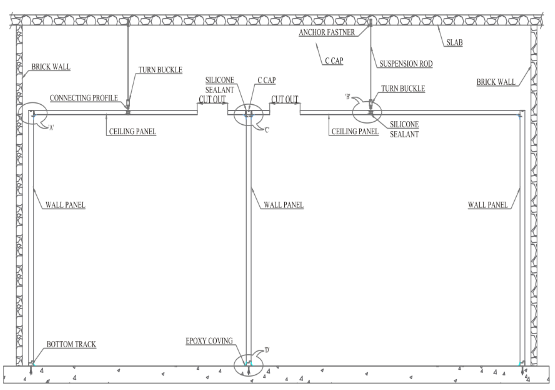

Cleanroom ceiling system is mainly composed of modular cleanroom panel and ceiling system. The ceiling system can be perfectly connected with the modular cleanroom panel system products. The ceiling system connection gap is the same as the gap width to ensure the appearance of a clean room. cleanroom panel sheet is very resistant to bending and has very strong characteristics. The ceiling membrane is of vital importance to the integrity and performance of any cleanroom. The concept of ceiling can vary from simple suspended lay-in grid types to sophisticated ‘Walk on construction plenums.

The INNOVUS ‘Walk on ceiling’ is a product that offer amazing option in creating custom and system build solutions the most complicated of enclosures for the demanding environments of the cleanroom users. Subject to specifications, each plank will hold a superimposed load of 25Kg/m2 together with point load 100 kilos.

| Types of Panel | Progressive / Non Progressive |

| Panel Thickness | 50 mm / 60 mm / 80 mm |

| Infill | PUF (40 kg/M3) / Rockwool (96 kg/M3 ) / Honeycomb Paper |

| Size Range | 1200max width to 3000mm Length |

| Sheet Thickness | 0.6 / 0.8 / 1.0 mm |

| Sheet Finish | Pre-Painted GI (PPGI) / Powder Coated GI (PCGI) / SS 304 |

| Panel Connection | Aluminum / GI interconnecting profile |

| Surface Finish | Pure / Epoxy Polyester Powder coated as per RAL colours, SS Finish |

| Ceiling Suspension | |

| Factory Made and Site Made Cutout as per Design. | |